Scientific American Supplement, No. 799, April 25, 1891 by Various, is part of the HackerNoon Books Series. You can jump to any chapter in this book here. THE POWER OF WATER, OR HYDRAULICS SIMPLIFIED.

THE POWER OF WATER, OR HYDRAULICS SIMPLIFIED.

By G.D. Hiscox.

CURRENT WHEELS FOR POWER AND RAISING WATER.

The natural flow of water in a current is probably one of the oldest and cheapest of the methods for obtaining power, or the lifting of water within moderate elevations, for a supply for irrigation and domestic purposes; and we propose, apart from the current wheel, to treat only of self-water-raising devices in this chapter.

Water wheels of various forms for this purpose have been used from time immemorial in Europe, Asia and Egypt, where the record gives examples of wheels of the noria class from 30 to 90 feet in diameter; the term noria having been applied to water wheels carrying buckets for raising water; the Spanish noria having buckets on an endless chain.

Records of a Chinese noria, of 30 feet diameter, made of bamboo, show a lifting capacity of 300 tons of water per day to a height of ¾ of the diameter of the wheel—velocity of current not stated.

For less quantity and greater elevation, these forms of wheel may have pumps attached to the shaft, by crank, that will give a fair duty for a high water supply.

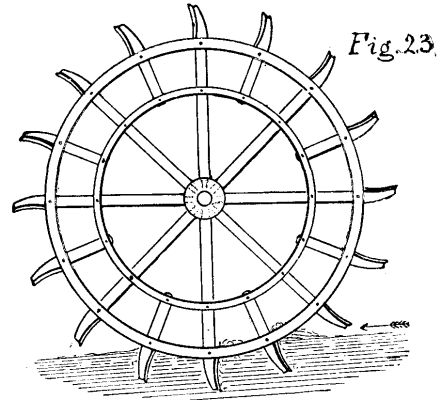

For power purposes, as in the plain current wheel, Fig. 23, there are two principal factors in the problem of power—the velocity of the current and the area of the buckets or blades.

Their efficiency is very low, from 25 to 36 per cent., according to their lightness of make and form of buckets. A slightly curved plate iron bucket gives the highest efficiency, thus ( to the current, and an additional value may also be given by slightly shrouding the ends of the buckets.

The relative velocity of the periphery of the wheel to the velocity of the current should be 50 per cent. with curved blades for best effect.

The most useful and convenient sizes for power purposes are from 10 to 20 feet, and from 2 to 20 feet wide, although, as before stated, there is scarcely a limit under 100 feet diameter for special purposes.

In designing this class of wheels special attention should be given to the concentration and increase of the velocity of the current by wing dams or by the narrowing of shallow streams; always bearing in mind that any increase in the velocity of the current is economy in increased power, as well as in the size and cost of a wheel for a given power.

The blades in the smaller size wheels should be 1/4 of the radius in width, and for the larger sizes up to 20 feet, 1/5 to 1/6 of the radius in width and spaced equal to from 1/4 to 1/3 of the radius.

They should be completely submerged at the lowest point.

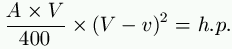

For obtaining the horse power of a current wheel, the formula is

Area of 1 blade × velocity of the current in ft. per sec.

----------------------------------------------------------

400

× by the square of difference of velocities of current and wheel periphery = the horse power; or

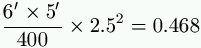

in which A equals the area of blade in square feet, V and v velocities of current and wheel periphery respectively, in feet per second. Thus, for example, a wheel 10 feet in diameter with blades 6 feet long and 1 foot in width, running in a stream of 5 feet per second—assuming the wheel to be giving as much power as will reduce its velocity to one half that of the stream—the figures will be

horse power of the wheel.

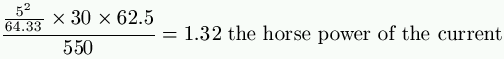

The total power of the stream due to the area of the blade equals the

Square of the velocity of the stream

------------------------------------ ×

Twice gravity (64.33)

volume of water in cubic feet per second × 62.5 (weight of 1 C') = the value or gross effect in pounds falling 1 foot per second. This sum divided by 550 = horse power. Thus, as per last example,

due to the area of the blades of the water wheel.

For the efficiency of this class of wheel, with slightly curved and thin blades, divide the horse power of the wheel by the horse power of the current area, equals the percentage of efficiency.

As in the last case,

0.468 / 1.32 = 0.35½

per cent. efficiency of the water wheel.

With higher velocities of stream and wheel the efficiency will be from 2 to 3 per cent. less, although the horse power will increase nearly with the increase in velocity of the current.

For details of application of various forms of current wheels for power purposes see illustrated description Yagn's and Roman's floating motors in SCIENTIFIC AMERICAN SUPPLEMENT, No. 463.

A very good example of a floating motor of the propeller class is Nossian's fluviatile motor, illustrated and described in SCIENTIFIC AMERICAN SUPPLEMENT, No. 656.

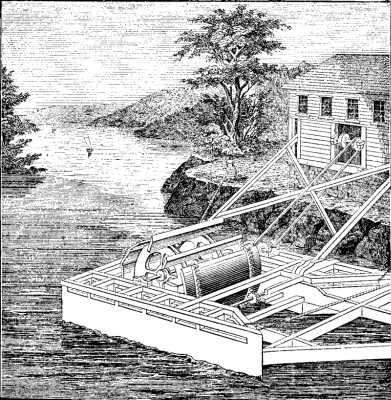

Fig. 24 represents a very complete floating motor, in which the floats are wedge shaped at the stem, for the purpose of increasing the current between them, the wheel being an ordinary current wheel, as shown in Fig. 23, with a curved shield or gate in front, which can be moved around the periphery of the wheel for the purpose of regulating its speed or stopping its motion by cutting off the stream from the buckets.

The float, rising and falling with the stream, is held in position by a braced frame swinging on anchorages within the mill on shore, and parallel with a swiveled shaft.

Tide wheels and tidal current wheels have been in use for more than 800 years, and were largely in use in Europe and the United States during the first half of the present century. No less than three were running in the immediate vicinity of New York, in 1840, for milling purposes.

Their day seems to be past, except in some special localities. We will also pass them, and illustrate some of the

SELF-ACTING WATER-RAISING DEVICES.

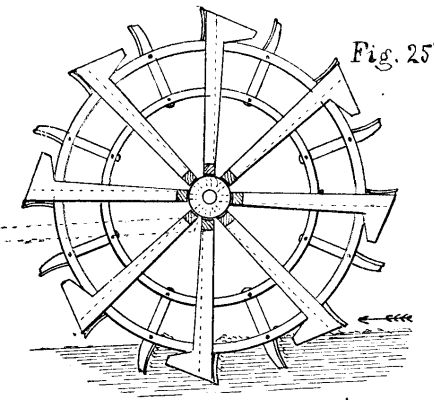

The tympanum derives its name from its similarity to a drum as made by the Romans, but its origin was Egyptian. It is a current wheel with frame like Fig. 23, to the outside of which a set of chambers or tubes are fixed, radiating spirally, so as to lead the water to the shaft as the wheel revolves, as shown in Fig. 25. It has a lift of a little less than half its diameter, and answers an excellent purpose for the irrigation of rice and cranberry fields, or on streams running through low lands in arid districts. It is still one of the Nile irrigating wheels.

The building of these wheels is within the scope of the carpenter and the tinsmith. A short wooden shaft made square or octagonal, as convenient, with gudgeons in the ends and arms of wood bolted across each of the sides of the shaft, or as shown in the cut, will form a frame work upon which a rim may be fastened, to which the blades and tubular buckets can be attached.

The directions in regard to the current wheel, Fig. 23, may be followed as to number and form of blades, which must be made in length and width proportional to the velocity of the stream and the quantity of water to be lifted by each tubular arm. The tubes may be made of galvanized sheet iron and attached to the outside of the wheel, as shown in Fig. 25.

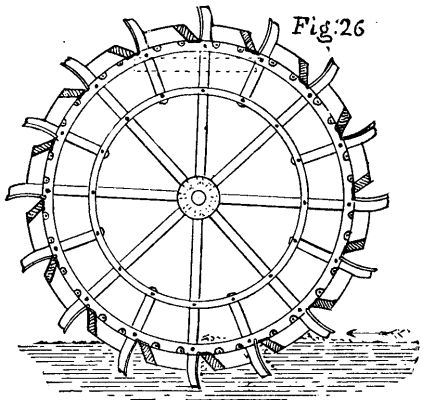

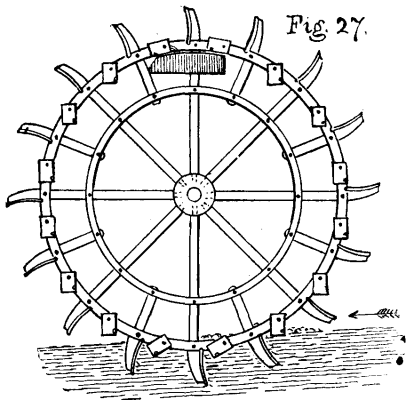

THE NORIA OR BUCKET WHEEL.

This is a simple current wheel with pot buckets, rigid or swinging, arranged on the rim of the wheel, to carry up and discharge the water nearly at the top of the wheel, and through the long ages that it has been in use for irrigation, village water supply, and even for private establishments, has assumed a variety of forms in detail of construction ranging from the bamboo wheels of the Chinese to the light iron wheels of modern construction.

We illustrate the most simple of these forms in Figs. 26 and 27, in which the first is a series of boxes or chambers in the rim of the wheel with side openings in the forward part of the box as the wheel revolves, and a lip extending from the inner edge of the opening to direct the outflow into the trough.

Another form, Fig. 27, is arranged with swing buckets or pots, pivoted just above their centers, and with the catch trough so fixed as to tip the buckets at the highest point, thus giving this wheel the greatest possible advantage as to height of discharge for a given diameter.

The power value of these wheels for raising water is a matter of computation as nearly reliable as for other devices for the same purpose, when the velocity of the current is known at the point of contact with the blades.

The horse power of the wheel may be computed as for the current wheel, Fig. 23, and, as the horse power is equal to 33,000 pounds raised one foot high per minute, we may assume a construction of wheel that will allow of discharging at 8 feet above the stream; then 33,000 / 8 = 4,125 pounds of water discharged at 8 feet elevation per horse power per minute. As the net power of the wheel in the last example, for Fig. 23, was 0.468 of a horse power, then 4,125 × 0.468 = 1,930 pounds of water raised 8 ft. per minute by the size of bucket and velocity of current in that case. From this a deduction of 20 per cent. should be made for loss by spill and imperfect construction, so that 1,500 pounds or 176 gallons per minute would be the probable output—over 253,000 gallons per day; or, for irrigating purposes, equal to a rainfall of over 1¼ inches in depth on 50 acres in one week.

The proportion of capacity of the lifting buckets for such a wheel becomes of as great importance as its efficiency.

If the buckets are too large, the wheel will stall, and if too small, the wheel will not give its full duty.

For obtaining the approximate capacity of the lifting buckets, assuming the example as above computed, a 10 foot wheel with the velocity at periphery of 2½ feet per second is 150 feet per minute, or five revolutions per minute, nearly. Then 1,930 lb. per m. / 5 revolutions = 386 pounds water capacity for all of the buckets on the wheel.

If such a wheel is constructed with 16 blades and 16 buckets, one between each blade, then 386 / 16 = 24 pounds for each bucket, or 38 / 100 of a cubic foot.

The spill from this capacity of bucket being sufficient to compensate for the friction of the shaft journals.

The lifting buckets of the noria class, Figs. 26 and 27, can be made of positive dimensions to suit the computations as above; but those of the tympanum class, Fig. 25, should be made of dimensions to conform with the required capacity at the moment of leaving the water, as the water at this point flows into the arm.

(To be continued.)

About HackerNoon Book Series: We bring you the most important technical, scientific, and insightful public domain books.

This book is part of the public domain. Various (2004). Scientific American Supplement, No. 799, April 25, 1891. Urbana, Illinois: Project Gutenberg. Retrieved https://www.gutenberg.org/cache/epub/11649/pg11649-images.html

This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org, located at https://www.gutenberg.org/policy/license.html.